Standard Features

Twin-channel Detection System

Twin-channel data acquisition and transmission technology to process and display the images from different angle scanning synchronically.

High Definition Image

Adopt new generation of HD schema design, providing clear images and stable performance.

Dynamic Processing

Real-time display, optimization functions like edge enhancement, amplification and so on.

Image Management

Built-in image management system, which enables users to browse saved images quickly.

Intelligent Alarm

User can set the alarm threshold, and realize acousto-optic alarming prompt when the impermeable items are detected.

Green Lead Curtain

Wear-resistant, pollution-free, long service life.

Self-Diagnose

Automatically prompt when failure is detected, and be convenient to maintain.

Shutdown With One Key

When you try to turn off the equipment, just rotate the key, which is convenient and simple.

Network Interface

Use standard Ethernet port to transmit images with rapid processing and great anti-interference performance.

Intelligent Roller

Roller will automatically rotate when there is luggage on the conveyor belt, otherwise, the roller will stop rotating making this product environmental-friendly and energy-saving.

Threat Image Protection

TIP is fully configurable by high level users, where parameters such as type of threats, frequency of projection etc. can be configured.

Usage/Application | Checkpoint,Hotel, Checkpoint, Shopping mall, Customs, Port, Gym, Warehouse etc | —— | Image System |

|

General Parameters |

|

| X-ray Sensor | L-shaped photo diode array (mono energetic), 16bit depth |

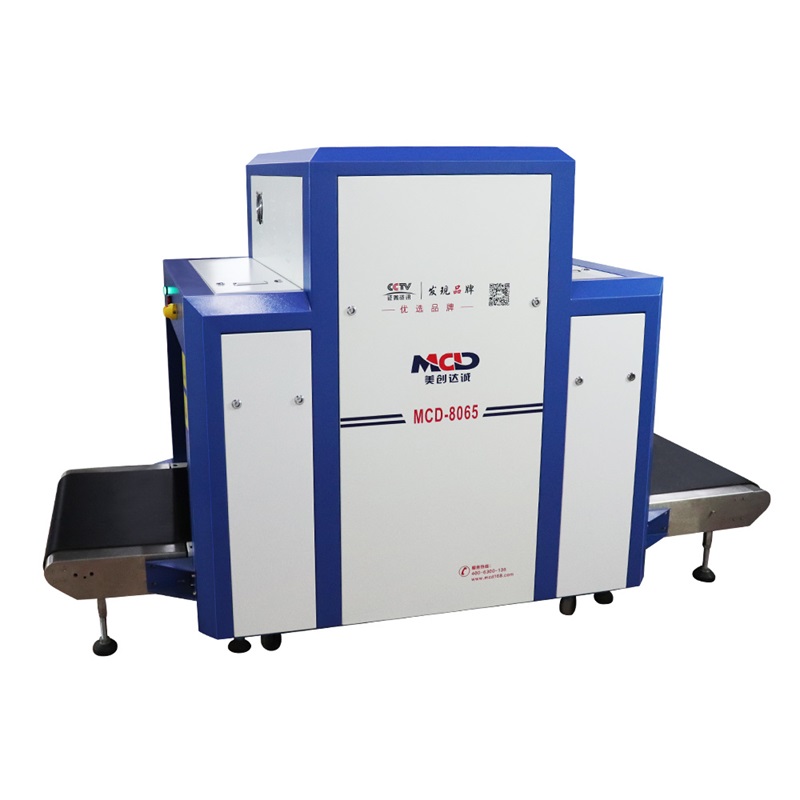

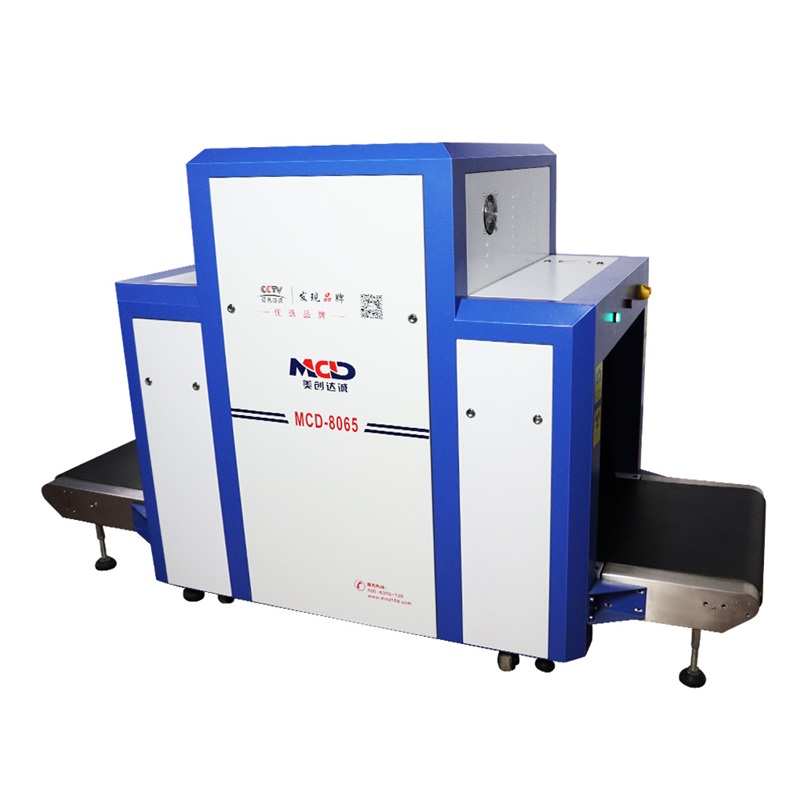

Model number | MCD-8065A |

| Monitor | High resolution color, LCD compatible, 19inch |

Tunnel Size Conveyor | 800 mm (Width) * 650 mm (Height)) |

| Image Processing | Edge enhancement, image enhancement, image lighting, reduction of darkening, image reversion, image rewind. |

Conveyor Speed | 0.22/ sec

|

| Image Grayness Level | 4096 |

Conveyor Max Load | 200 kg (Evenly distributed) |

| Image Maximum Resolution | 1024*768 pixels |

Pass resolution | 32AWGΦ0.202mm |

| Image Processing | 24bit real time processing in real time |

Metal Wire Resolution | 40AWG / Φ0.202 mm |

| Image Storage | 60,000 images in real time |

Spatial Resolution | Level: dia 1.0 mm Vertical: dia 1.3 mm |

| Energy | Multi-energy (High-energy/low energy) |

Penetration Through Steel Plate | 14 mm |

| Zone & Zoom | 1-9 image zones, enlargement of 2, 4, 8, 16 times, fully screen continuous observation. |

Dose per Inspection | Less than 1.0 uGy/h |

|

|

|

Film Safety | Guaranteed ISO 1600 Film |

| Installation Data |

|

X-ray Leakage | Less than 1 uGy/h at 5cm from frame house |

| Operating Environment / Humidity | 0 to 45 Degree C / 20 - 95% (non-condensing) |

*With continued R&D, MCD reservers the right to amend specifications without notice. |

| Storage Temperature / Humidity | -20 to 60 Degree C / 20 ~ 95% (non-condensing) |

X-ray Generator |

| Operating Power | 220VAC (± 10%) 50 ± 3Hz |

Generator Direction | From top to bottom |

| Power Consumption | 1.0 KW (max), 0.3KW (working) |

Generator Angle | 80 degrees downward |

| System Noise | <55 dB |

Anode Voltage | 80KV |

|

|

|

Anode Power | 0.6 mA |

| Package Size |

|

X-ray Sensor | single generator |

| Unit Net Weight | 500 Kgs |

Cooling/Duty Cycle | 0%-90% (non-condensing) |

| Unit Gross Weight | 650 KG |

|

|

| Wooden size | 218 (L) x 108 (W) x 150 (H) cm ( Xray Device) 132 (L) x 120 (W) x 78 (H) cm (Xray Device Computer) |

|

| CBM | 8 CBM |

| Ready to ship |  | Warranty Policy |  | Customer Support |

| The Order is shipped the same day | Warranty period within 1 Year | sales@mcddetection.com |